Services & Capabilites

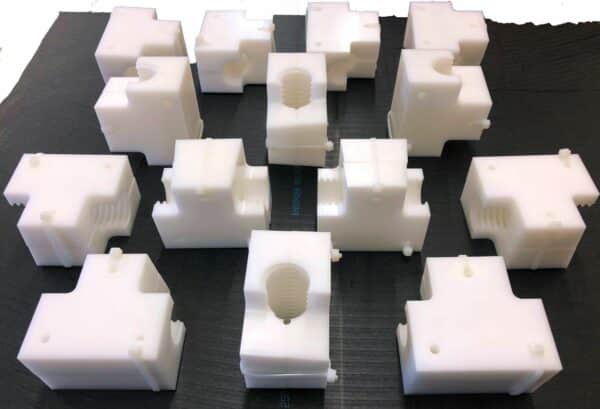

Plastic CNC Milling and Turning Solutions

Plastic CNC milling and turning involves the process of shaping and forming plastic materials to create finished products. At Thirty Two Machine, we utilize advanced techniques and state-of-the-art equipment to fabricate plastic components with precision and efficiency.

Our Approach

At Thirty Two Machine, we are dedicated to delivering top-quality plastic fabrication services tailored to your specific needs. Our skilled team of technicians utilizes advanced fabrication techniques and precise machining equipment to ensure the highest level of accuracy and consistency in every component we produce. From CNC routing and laser cutting to thermoforming and welding, we have the capabilities to handle projects of varying complexity with efficiency and precision.

Why Choose Us?

- Expertise: With years of experience in plastic CNC milling and turning, we have the knowledge and skill to tackle even the most challenging projects.

- Precision: We adhere to strict quality control standards to ensure that every plastic component meets the highest standards of precision and accuracy.

- Versatility: Whether you require prototyping, low-volume production, or high-volume manufacturing, we can accommodate projects of any size and scale.

- Customer Satisfaction: Your satisfaction is our priority. We work closely with you to understand your requirements and deliver solutions that meet or exceed your expectations.